Forklifts - Description & Inspection Parameters

A forklift (also called lift truck, fork truck, fork hoist, and forklift truck) is a powered industrial Truck used to lift and move materials over short distances. The forklift was developed in the early 20th century by various companies, which made hoists. Since World War II, the use and development of the forklift truck have greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing.

| Classification | Vehicle |

| Industry | Various |

| Application | Multiple |

| Fuel source |

Various including:

|

Gasoline

|

|

Propane

|

|

CNG

|

|

Diesel

|

|

Lead Acid Battery

|

|

Fuel cell

|

|

Powered |

Yes |

Wheels |

Various wheel configurations |

| Axles | 02-Mar |

Components |

Power source, Mast, Frame, Counterweight, Cab, Axles, Wheels, Overhead Guard, Load Backrest, Hydraulic Pump, Hydraulic Lines, Hydraulic Controls, Hydraulic Cylinders and Attachments |

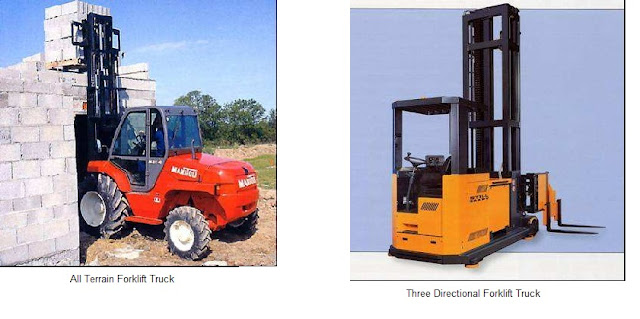

There are various types of forklifts used in industrial sectors. The most common forklifts are mentioned below -

1. Carried Conductor

2. Stand-up Rider Forklift Truck

3. Forklift Truck with retractable mast

4. Quad-directional Forklift Truck

5. All Terrain Forklift Truck

6. Three-directional Forklift Truck

7. Forklift Truck with Side Loading

8. Telescopic forklift

9. Reach Truck

10. Electrical Forklift

Electrical Forklift

Pay attention that

some

forklift-trucks are fitted out with

hydraulic telescopic booms!

In this case,

consider they are deemed

and used as "Mobile Cranes".

The main accessories & components of a Reach Truck is shown in the below picture.

Thorough Inspection Parameters & Checkpoints

The objective of

this guide is to define minimum requirements for in-service inspections and should be mandatory used, unless a specific regulation in force is available in

a country. In this latter case, the criteria enclosed could be added for a professional management of a lifting equipment park.

This is the

free synthesis of

the following:

Lifting Operation and Lifting Equipment Regulations 1998 (LOLER),

French Regulation which came in force on March 1st

2004 for inspection of

lifting equipment and their

hoisting accessories,

DESCRIPITION

|

CONDITION / REMARKS / PERFORMANCE TESTS

|

|

0

|

GENERAL DESCRIPTION OF THE

EQUIPMENT

|

|

1.1

|

Access to the cab, to the cockpit

|

|

3

|

FRAMING

|

|

3.4

|

Connections, brackets,

assemblies, joints

|

|

3.10

|

Mast, ladder

|

|

3.11

|

bumper plate, bumpers

|

|

4

|

CHASSIS

|

|

4.4

|

Running gear (caterpillars,

pneumatic,

...)

|

|

4.5

|

Frame, counterweight

|

|

4.7

|

Stabilizers

|

|

5

|

SOURCE OF ENERGY

|

|

5.1

|

Power supply limitation

|

|

5.2

|

Equipement, wiring system,

coiling units

|

|

6

|

LIGHTING INCORPORATED IN THE

UNIT

|

|

6.2

|

Lighting, signing,

traffic lights,

flashing beacons

|

|

7

|

CAB - DRIVER'S CAB

|

|

7.2

|

Constitution, fastening devices,

foot rack

|

|

7.5

|

Operator's protection

|

|

7.6

|

Protection of the accessible mobile

elements

|

|

7.7

|

Seat, seat belt

|

|

7.8

|

Working visibility (glass transparency, windshield wipers,

rearview mirror)

|

|

7.12

|

Seat

|

|

8

|

OPERATING AND MATERIALS

HANDLING DEVICES

|

|

8.1

|

Start / Stop

|

|

8.2

|

Lock-out of use (tagging out)

|

|

8.3

|

Other emergency stops

|

|

8.4

|

Indicators,

signalling and warning devices

|

|

8.5

|

Identification of control devices

|

|

8.6

|

Automatic return to neutral point

|

|

8.7

|

Warning signals

|

|

8.9

|

Protecting devices against unwilling or non-voluntary operations

|

|

8.15

|

Other unit(s), drawbar

|

9

|

MAIN RUNNERS, GUYS, DRUMS,

PULLEYS, FASTENING

DEVICES

|

|

9.1

|

Fasteners,

clips, straps, clamps

|

|

9.2

|

Fastening devices

|

|

9.4

|

Main

runners and lines,

guys (wire

ropes or chains)

|

|

9.5

|

Drums, pulleys, rope blocks, drive

pinions, windlasses

|

|

10

|

MECANISMS

|

|

10.1

|

Speed-limiting device (no runaway)

|

|

10.2

|

Locking devices and any other

brakes

|

|

10.5

|

Hoist brake

|

|

10.6

|

Power and gear

transmission system

|

|

10.16

|

Travel

brake and parking brake

|

|

11

|

SAFETY DEVICES

|

|

11.1

|

Limit stops relating to lifting motions

|

|

11.37

|

Security drawbar

|

|

11.38

|

Control of the forklift by the driver

|

|

14

|

PROOF LOAD TESTS

|

|

14.1

|

Static proof load

test

|

|

14.2

|

Dynamic proof load test

|

No comments:

Post a Comment